nut and bolt size chart pdf

Nut and bolt size charts provide essential guidance for selecting the correct fasteners, ensuring compatibility and safety in various applications. These charts typically include metric and imperial sizes, torque values, and material specifications. They help users match bolts with corresponding nuts, washers, and threaded rods, simplifying hardware selection for projects. Understanding these charts is crucial for maintaining structural integrity and preventing failures in mechanical systems.

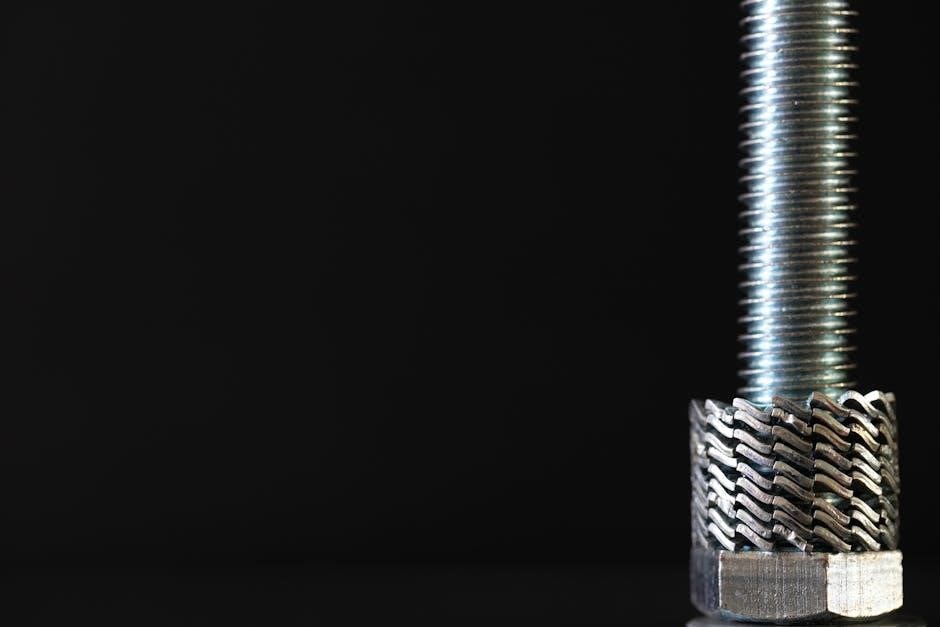

Overview of Bolt and Nut Size Standards

Bolt and nut size standards are established to ensure compatibility, safety, and consistency across applications. International standards like ISO and DIN regulate metric sizes, while SAE standards govern imperial sizes. These standards specify thread types, diameters, and lengths for bolts and corresponding nuts, ensuring proper fitment. Torque values, material grades, and finishes are also defined to meet performance requirements. Adhering to these standards helps prevent mechanical failures and ensures reliability in construction, automotive, and industrial applications. They provide a unified system for manufacturers and users to select the right fasteners efficiently.

Importance of Using a Nut and Bolt Size Chart

Using a nut and bolt size chart is crucial for ensuring proper fastener selection, preventing mechanical failures, and optimizing safety in applications. These charts provide precise measurements, torque values, and compatibility data, enabling accurate matching of bolts and nuts. Incorrect pairing can lead to structural weaknesses, corrosion, or even catastrophic failures. By adhering to size charts, users can avoid costly errors, reduce assembly time, and maintain compliance with industry standards. This ensures reliable performance, durability, and safety in machinery, vehicles, and construction projects, making these charts indispensable tools for engineers and technicians.

Standard Bolt and Nut Size Charts

Standard bolt and nut size charts provide detailed measurements for metric and imperial fasteners. They include torque specifications, material compatibility, and thread types, ensuring proper assembly and safety.

Metric Bolt and Nut Sizes

Metric bolt and nut sizes are standardized based on ISO specifications, ensuring consistency worldwide. Measurements typically include diameter, thread pitch, and length. Common sizes range from M6 to M24, with thread pitches like 1.0 or 1.5mm. Nuts correspond to bolt diameters, with options like Nyloc or flange types. Charts often detail maximum and minimum tolerances, crucial for precise fitting. Thread designations (e.g., M12x1.5) specify diameter and pitch. Proper sizing ensures structural integrity and prevents failure in mechanical applications. Metric systems are widely adopted in industries for their uniformity and reliability in engineering projects.

Imperial Bolt and Nut Sizes

Imperial bolt and nut sizes are standardized in inches, with common diameters ranging from 1/2″-13 to 1″-14. These measurements are typically outlined in SAE and ASME specifications. Bolt sizes include thread diameter and pitch, such as 1/2″-13, indicating a half-inch diameter with 13 threads per inch. Nuts are matched to bolt sizes, ensuring compatibility; Thread types include UNC (coarse) and UNF (fine), each suited for different applications. Charts often list torque values and wrench sizes, aiding in proper tightening. Imperial sizes are widely used in machinery and construction, requiring precise alignment to ensure safety and durability in structural applications.

SAE Bolt and Nut Torque Value Chart

The SAE Bolt and Nut Torque Value Chart provides essential torque specifications for bolts and nuts, ensuring proper tightening in various applications. It includes torque values for different bolt grades, such as Grade 5 and Grade 8, and specifies thread types like UNC and UNF. The chart helps users determine the correct torque for a given bolt-nut combination, based on diameter and thread type. This ensures safety and reliability in mechanical systems. Proper torque application prevents over-tightening or under-tightening, which can lead to material failure. The chart is a critical resource for engineers and technicians working with imperial fasteners.

Manufacturers and Suppliers of Bolts and Nuts

Leading manufacturers provide high-quality bolts, nuts, and related hardware, adhering to international standards like DIN and ISO. They supply various fasteners, including threaded rods, U-bolts, and self-locking nuts.

Top Manufacturers in the Industry

Leading manufacturers like Bolt Depot and others specialize in producing high-quality bolts, nuts, and fasteners. They offer a wide range of metric and imperial sizes, ensuring compatibility with global standards. These manufacturers provide detailed size charts, such as the nut and bolt size chart PDF, to help users select the right hardware. Their products include U-bolts, threaded rods, and self-locking nuts, catering to industries like automotive, construction, and aerospace. By adhering to strict quality control and international standards, these manufacturers ensure reliability and durability in their fasteners, making them trusted suppliers worldwide.

Threaded Rod and U-Bolt Sizes Chart

Threaded rods and U-bolts are essential components in fastening systems, offering versatility for various applications. A threaded rod size chart provides detailed specifications, including diameter, length, and thread type, ensuring compatibility with nuts and washers. U-bolt sizes charts outline bend radius, thread length, and dimensions, critical for securing pipes, beams, and other structural elements. These charts are often included in nut and bolt size chart PDF documents, offering a comprehensive guide for engineers and technicians. They ensure proper fitment, load-bearing capacity, and durability in industrial and construction projects, making them indispensable tools for precise hardware selection.

Bolt and Nut Materials and Finishes

Bolts and nuts are crafted from durable materials like stainless steel, zinc, and nylon, ensuring resistance to corrosion and wear. Finishes such as galvanized or chrome-plated enhance longevity and aesthetics, catering to specific applications and environmental demands.

Common Materials Used for Bolts and Nuts

Bolts and nuts are typically made from materials like stainless steel, carbon steel, brass, and nylon. Stainless steel offers excellent corrosion resistance, while carbon steel provides high strength. Brass is ideal for electrical applications, and nylon is lightweight and resistant to chemicals. Other materials include titanium, aluminum, and zinc, each suited for specific environmental conditions. The choice of material depends on factors like load-bearing requirements, temperature, and exposure to corrosive substances. Proper material selection ensures durability and reliability in fastening applications, making it a critical consideration in engineering and construction projects.

Finishes and Coatings for Bolts and Nuts

Bolts and nuts are often finished with protective coatings to enhance durability and resistance to corrosion. Common finishes include zinc plating, galvanizing, chrome plating, and epoxy coatings. Stainless steel and titanium fasteners inherently offer corrosion resistance without additional treatments. Nylon and ceramic coatings provide insulation and chemical resistance. Specialized finishes like cadmium or phosphate are used in high-stress environments. These coatings not only extend the lifespan of fasteners but also ensure optimal performance in various conditions. The choice of finish depends on the application, environmental factors, and required aesthetic appeal, making them a vital aspect of fastener specification and selection.

Bolt and Nut Installation and Safety

Proper bolt and nut installation ensures structural integrity and safety. Always use torque wrenches for precise tightening, and ensure bolts are seated correctly to avoid failure risks.

Methods of Applying Tension to Bolted Connections

Applying tension to bolted connections is critical for ensuring structural integrity. Common methods include using torque wrenches for precise control, hydraulic tensioners for high-pressure applications, and manual tightening for simpler projects. Each method ensures proper preload, preventing bolt loosening and material failure. Torque wrenches are widely used due to their accuracy, while hydraulic systems offer uniform tension across multiple bolts. Proper tensioning methods are essential for safety and performance in mechanical systems, as outlined in bolt and nut size charts and technical specifications.

Self-Locking Counter Nuts and Their Applications

Self-locking counter nuts are designed to provide secure, vibration-resistant connections, ideal for dynamic environments. They feature unique thread designs or deformable materials that create friction, preventing loosening under stress. Applications include machinery, automotive suspension systems, and aerospace components. DIN 7967 standards outline their dimensions and specifications, ensuring reliability. These nuts eliminate the need for additional locking mechanisms, reducing assembly time and costs. Their versatility and durability make them a preferred choice in industries requiring high-performance fastening solutions, as detailed in bolt and nut size charts and technical specifications.

The evolution of bolt and nut technology continues, with advancements in materials and smart fasteners. Future trends focus on sustainable materials, automation, and digital integration for enhanced performance and efficiency.

Evolution of Bolt and Nut Technology

Bolt and nut technology has evolved significantly, driven by industrial demands for strength, durability, and precision. Early bolts were simple, with limited material options, but advancements in metallurgy introduced high-strength alloys. Standardization efforts, like ISO 225, ensured consistency across manufacturers. Modern innovations include lightweight materials for aerospace and corrosion-resistant coatings. Smart fasteners now integrate sensors for real-time monitoring. Sustainable practices are reshaping production, prioritizing eco-friendly materials and energy-efficient processes. These advancements reflect a commitment to reliability, versatility, and efficiency, paving the way for future innovations in fastening solutions.

Future Trends in Fastener Design

Future trends in fastener design emphasize innovation, sustainability, and integration with advanced technologies. Smart fasteners embedded with sensors for real-time monitoring are gaining traction, enabling predictive maintenance. Lightweight, high-performance materials like advanced alloys and composites are being developed for aerospace and automotive industries. Sustainable manufacturing practices, such as energy-efficient production and recyclable materials, are becoming priorities. Additionally, AI-driven design tools are improving customization and optimization of fasteners for specific applications. These advancements aim to enhance durability, reduce environmental impact, and meet the evolving needs of modern engineering, ensuring faster, safer, and more efficient solutions for industries worldwide.