manual calculo para doblar tubos

Accurate calculations are crucial for successful tube bending, ensuring precise results and minimizing errors. Key factors include material properties, bend radius, and wall thickness to achieve optimal outcomes.

Importance of Accurate Calculations in Tube Bending

Accurate calculations are essential for achieving precise and reliable results in tube bending. They ensure the correct bend radius, angle, and material deformation, preventing defects like kinking or flattening. Incorrect calculations can lead to material waste, equipment damage, or even safety hazards. Proper measurements, such as outer diameter and wall thickness, are critical to determine the right bending force and tools. Additionally, understanding the relationship between the bend radius and the tube’s properties helps avoid over-stressing the material. In industries like plumbing or automotive, precise bends are vital for functionality and safety. Thus, accurate calculations are the foundation for successful tube bending, ensuring efficiency and quality in every application.

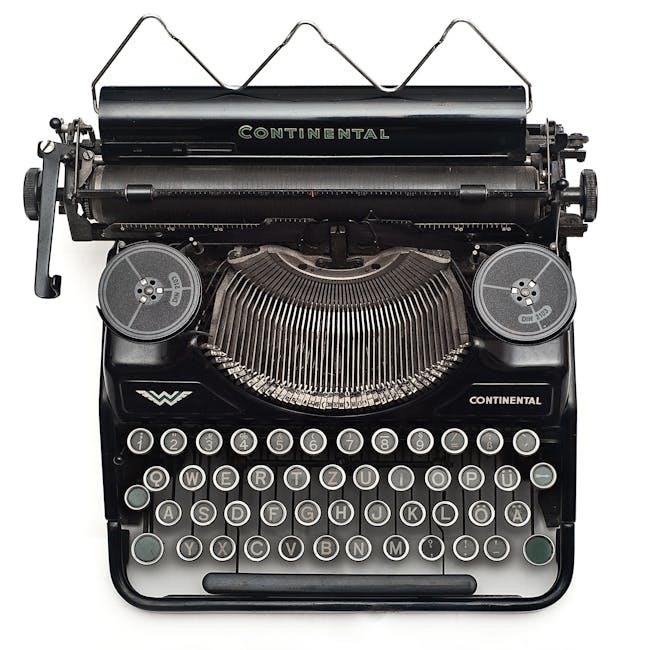

Brief History and Evolution of Tube Bending Techniques

The history of tube bending dates back to ancient civilizations, where early metalworkers manually shaped tubes for tools and infrastructure. Initially, bending was done by hand or with simple tools, relying on trial and error. The Industrial Revolution introduced mechanical bending machines, enabling more precise and scalable production. Over time, advancements in materials science and engineering led to the development of modern tube bending techniques. Today, computer-aided designs and CNC machines allow for highly accurate calculations and reproducible results. Despite these advancements, manual calculations remain fundamental, ensuring that even complex bends meet specifications. This evolution reflects humanity’s ingenuity in adapting techniques to meet growing demands for precision and efficiency in industries like plumbing, automotive, and construction.

Essential Considerations Before Bending

Understanding the tube’s material, outer diameter, wall thickness, and temperature is critical to ensure precise calculations and safe bending. These factors directly influence the bending process’s success and accuracy.

Understanding Tube Material and Thickness

Understanding the tube’s material and thickness is vital for accurate bending calculations. Different materials, such as steel, aluminum, and copper, have unique properties that affect flexibility and bending ease. Tube thickness, measured as the wall thickness, determines the required bending force and tooling. Thicker walls are more rigid and may demand specialized equipment, while thinner walls are more prone to deformation. Measuring the tube’s outer diameter and wall thickness ensures precise calculations for bend radius and angle. Material hardness and flexibility also influence the bending process. For instance, softer materials like copper can be bent more easily than harder materials like stainless steel. Accurate measurements and material analysis are essential to avoid defects and ensure a successful bend. Always consult material specifications to determine the appropriate bending parameters for your project.

Measuring the Tube’s Outer Diameter

Accurately measuring the tube’s outer diameter is a critical step in the bending process. Use a caliper or precision tape measure to obtain the diameter, ensuring multiple measurements along the tube for consistency. Record the average value to account for slight variations. This measurement is essential for calculating the bend radius and angle, as it directly influences the tooling and bending force required. For precise results, measure the tube when it is straight and unsupported to avoid compression or expansion. The outer diameter measurement also helps determine the appropriate die size for the bending machine. Always double-check your measurements to avoid errors in subsequent calculations. Accurate diameter measurement ensures the bend aligns with the desired specifications and prevents material deformation or cracking during the bending process.

Step-by-Step Bending Process

Mark the tube, calculate the bend radius and angle, apply the required bending force, and use tools like mandrels to ensure precise and defect-free bends every time.

Marking the Tube for Bending

Accurate marking is essential for precise tube bending. Begin by measuring the tube’s outer diameter using a caliper or tape measure to determine the correct bend radius and angle. Consider the tube’s material and thickness, as different materials require specific handling to avoid defects. Calculate the bend radius and angle using established formulas or tables, ensuring marks are placed correctly to guide the bending process. Use a marker or specialized tool to clearly indicate where the bend should start and end, possibly employing templates or gauges for alignment. Proper marking prevents errors like kinking or flattening, ensuring the tube bends as intended. Always double-check marks against calculated values before proceeding with bending to ensure accuracy and safety.

Calculating the Bend Radius and Angle

Calculating the bend radius and angle is critical for achieving the desired shape without damaging the tube. The bend radius is typically determined by multiplying the tube’s outer diameter by a factor, which varies based on the material and bending method. For instance, cold bending often uses R=(4-6)D, while hot bending may use R=4D. The bend angle is measured in degrees, commonly ranging from 30° to 180°, depending on the application. Using the Pythagorean theorem or specialized tables can help determine the exact measurements. Additionally, factors like wall thickness and material flexibility must be considered to prevent issues such as wrinkling or cracking. Precise calculations ensure the bend meets design specifications and maintains structural integrity. Always verify calculations with industry standards or manufacturer guidelines to ensure accuracy and safety.

Applying the Correct Bending Force

Applying the correct bending force is essential to avoid deforming the tube or causing material failure. The force required depends on the tube’s material properties, outer diameter, and wall thickness. For precise calculations, the bending force can be determined using torque equations or specialized software. Hydraulic benders are commonly used to apply controlled force, ensuring consistent results. The force must align with the tube’s yield strength and bending radius to prevent over-stressing. Incorrect force can lead to issues like wrinkling, cracking, or uneven bends. Always refer to material specifications and bending charts to determine the optimal force for the specific tube and bend requirements. Proper force application ensures the tube bends accurately while maintaining its structural integrity and desired shape.

Tools and Machinery for Tube Bending

Essential tools include hydraulic benders, mandrels, and dies. Hydraulic benders apply controlled force for precise bends, while mandrels prevent tube deformation. Dies shape the bend accurately, ensuring consistency and quality.

Types of Tube Benders and Their Uses

Tube benders come in various types, each designed for specific applications. Manual benders are cost-effective for small-scale projects, offering simplicity and portability. Hydraulic benders provide precision and force for complex bends, ideal for industrial use. CNC (Computer Numerical Control) benders offer advanced automation for high-precision, repetitive tasks. Additionally, there are rotary draw benders, known for their accuracy in producing tight radii, and mandrel benders, which prevent tube deformation during bending. Each type is selected based on factors like tube material, diameter, and desired bend radius. Specialized tools, such as the Swagelok bender, are used for creating precise, consistent curves in conduit and piping systems. Understanding the right bender for the job ensures efficient and accurate results in tube bending projects.

Importance of Mandrels in Bending

Mandrels are essential tools in tube bending, ensuring the tube maintains its shape and roundness during the bending process. They are placed inside the tube to prevent flattening or kinking, especially in thin-walled or brittle materials. Fixed mandrels are used for simpler bends, while articulated mandrels are employed for tighter radii or more complex curves. The mandrel’s size and type are determined by the tube’s material, thickness, and the desired bend radius. Proper use of a mandrel ensures precise, smooth bends and prevents structural damage to the tube. It also reduces the risk of wrinkles or deformations, making it a critical component for achieving high-quality results in tube bending operations. Effective mandrel selection and application are vital for the success of any bending project.

Factors Influencing the Bending Process

Material properties, temperature, and tooling significantly influence bending outcomes. Proper selection of mandrels and dies, along with precise calculations, ensures accurate results and minimizes deformation risks during bending operations.

Material Properties and Their Impact on Bending

Material properties play a critical role in tube bending, as they determine the feasibility and quality of the process. Yield strength, elongation, and hardness are key factors that influence how a tube behaves during bending. For instance, materials with higher elasticity, such as copper, can be bent more easily without cracking, while harder materials like steel require precise calculations to avoid deformation. Wall thickness is another crucial parameter, as thinner walls are more prone to kinking or flattening. Additionally, the thermal conductivity of the material may necessitate heating to achieve the desired bend radius. Understanding these properties ensures the selection of appropriate tools, such as fixed or articulated mandrels, to prevent defects like wrinkles or ovalization. Proper material selection and preparation are essential for achieving accurate and durable bends.

Temperature and Its Role in Bending

Temperature significantly influences the tube bending process, affecting both the material’s behavior and the final product’s quality. Heating the tube can reduce its yield strength, making it more pliable and easier to bend without cracking. This is particularly useful for materials like steel, which become more ductile at higher temperatures. However, excessive heat can lead to oxidation or annealing, potentially weakening the material. Conversely, bending at lower temperatures, known as cold bending, is common for materials like copper and aluminum, which retain their strength but require precise control to avoid kinking. The ideal temperature depends on the material type and the desired bend radius. Proper thermal management ensures a smooth, accurate bending process and prevents structural defects in the tube.

Common Defects and How to Avoid Them

Common defects in tube bending include cracking, wrinkling, and ovalization, which can ruin the structural integrity of the tube. These issues often arise from improper bend radius, insufficient support, or incorrect material selection. To prevent cracking, ensure the tube is heated adequately, especially for harder materials, and use a suitable mandrel to maintain roundness. Wrinkling can be avoided by using a deformer or adjusting the bending force to prevent excessive compression. Ovalization occurs when the tube flattens during bending; employing a close-radius die and maintaining precise control over the bending angle helps mitigate this. Regular maintenance of bending tools and adherence to material-specific guidelines further reduce the risk of defects, ensuring high-quality, consistent results in tube bending operations. Addressing these issues upfront saves time and material costs.